This Aluminum plastic board pulverizer machine could crush and separate Aluminum from the medical blister, ACP, plastic waste, and other materials. This machine has a large capacity and the different parts are connected through pipes, reducing dust pollution. For different raw materials, we provide different screening machines. Aluminum particles can directly process industrial aluminum powder such as aerated aluminum powder paste and aluminum powder for fireworks. The plastic powder can be processed into sheets, made into PVC and other materials.

Aluminum plastic board pulverizer Description

Aluminum plastic separation refers to the separation of aluminum-plastic composite materials into aluminum and plastic. The separation process adopts complete dry separation, which does not cause secondary environmental pollution and has good social and economic benefits.

Video of medical blister recycling machine

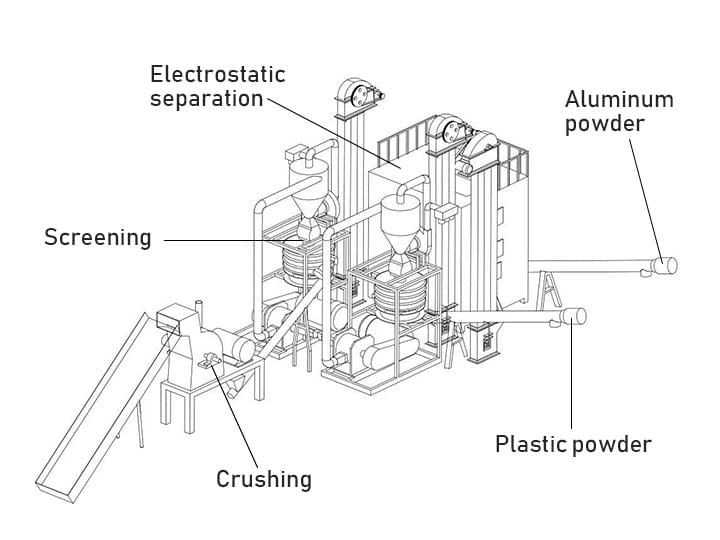

Machine structure of Medical blister recycling machine

Control panel, crusher, grinding machine, pulse dust collect, vibrating screen, electrostatic separator

Application of ACP recycling machine

The environmentally friendly aluminum plastic separator can separate various conductive materials from non-conductive materials, and separate metals from non-metals. Mainly used for waste printed circuit boards (copper and PCB), various medical boards, and aluminum-plastic boards. Food packaging bags, milk bags. Toothpaste skin, Wahaha bottle cap. Aluminum-plastic pipe, aluminum-platinum paper, metal beneficiation, etc. The separation effect is obvious.

Since cities have to eliminate a large amount of waste every year, the use of aluminum-plastic separation equipment can turn these wastes into treasures without secondary pollution. The use of environmentally friendly and energy-saving separation methods is used to produce, and the investment recovery effect is significant.

Raw materials of Medical blister recycling machine

pharma industry blister material

food packaging bag

Aluminum Composite Panel (ACP)

Final products of ACP recycling machine

Plastic powder

Aluminum powder

Technical parameter of Medical blister recycling machine

| Equipment name | Model | Qty |

| Belt conveyors | 600#Power:1.5kw | 1 set |

| Knife crusher | 600#Power:22kw | 1 set |

| Wind feeder | D160Power:5.5+1.1kw | 1 set |

| Aluminum-plastic pulverizer | ||

| Water-cooled mill | 600#Power:45kw | 1 set |

| Electromagnetic feeder | 160Power:0.15kw | 1 set |

| Wind feeding system | D133Power:5.5+1.1kw | 1 set |

| Rotary vibration screening machine | 800#Power:1.1kw | 1 set |

| Air-cooled machine | 1000#Power:1.1kw | 1 set |

| Circulating water chiller | 3PPower:3.2kw | 1 set |

| Pulse dust removal equipment | 24 bagsPower:3kw | 1 set |

| Electrostatic sorting machine | 1500#Power:4.5kw | 1 set |

| Electric control cabinet+ PLC automatic control | 2 sets |

Aluminum plastic board pulverizer Production process

Crushing → powder milling → screening → electrostatic separation → finished products (aluminum)

Aluminum plastic separator environmentally-friendly separation of aluminum-plastic products process: through coarse crushing, fine crushing, electrostatic separation to complete the dissociation of aluminum powder and plastic. The crushed materials form a mixture of aluminum-plastic powder and enter the specific gravity separator to extract most of the aluminum powder. The aluminum powder from the specific gravity separator contains a small amount of plastic fiber powder (about 2-5% content), and then enters the electrostatic separation equipment to extract the remaining fine metals. Due to a large number of raw materials for various waste aluminum-plastic products, the metal separation purity through high-voltage electrostatic separation equipment is as high as 99%, and a large aluminum powder recovery rate can be achieved.

Electrostatic Separator

The high-voltage electrostatic separation equipment adopts a complete mechanical separation method, does not require chemical test equipment and separation liquid, etc., completely dry separation, and the separation purity rate is above 95%, which can reach 99.9%. It can separate any metal and plastic mixtures such as aluminum-plastic panel scraps and tablet packaging materials, Wahaha caps, aluminum-plastic tubes, waste cables, circuit boards, etc. It is a new type of environmental protection equipment in environmental protection projects.

Advantages of PP PE Film Aluminum Foil Pulverizer

- The whole aluminum plastic board or other materials with a width of 180cm or less and a thickness of 14mm or less, as well as all kinds of agglomerates with a diameter of less than 180cm can be directly crushed and separated, and there are almost no restrictions on the raw materials.

- The entire process of aluminum-plastic separation is mechanically automated, and only 1-2 people are required to operate the production, which reduces the consumption of human resources.

- Each configuration of the aluminum-plastic separator is easy to install and has a variety of assembly methods. Customized design and assembly schemes can be made according to the customer’s existing site to solve site problems for customers.

Factors affecting the waste Aluminum plastic board pulverizer grinding machine

Take the processed raw materials as an example, the equipment configuration used for different raw materials is different. If the raw material to be processed is aluminum-plastic panels, the configuration of the equipment is rough: crusher-pulverizer-lifter-electrostatic separation;

However, if the raw material to be processed is an aluminum-plastic medical board, the equipment configuration must be equipped with a mill and a rotary vibrating screen on the basis of the aluminum-plastic board. For different raw materials, parts of the equipment are different, so the price is not the same.