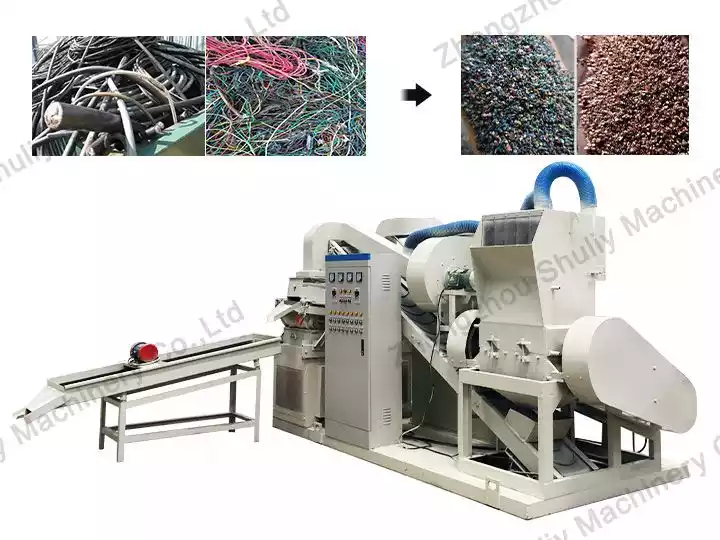

An aluminum wire recycling machine (also known as a copper wire granulator) is used to separate copper or aluminum from plastic after crushing. An aluminum cable recycling machine is a kind of environmental protection machinery, with a simple structure and mature technology.

The production principle of the dry aluminum plastic separator machine is mainly to use dry technology to pulverize and use specific gravity, magnetic, or electrostatic separation methods to separate non-metals and metals.

As a scrap wire recycling machine manufacturer, we can design and produce equipment with different sorting effects and reasonable outputs according to users’ needs. Aluminum wire recycling equipment can bring considerable benefits of resource recovery to customers.

Introduction to aluminum wire

Aluminum wire refers to a metal wire-shaped material made of pure aluminum or aluminum alloy. The cross-sectional shapes are circle, ellipse, square, rectangle, equilateral triangle and regular polygon, etc. According to the use, it is divided into industrial aluminum wire and process aluminum wire. The aluminum cable and wire are very light, the weight of the aluminum wire and cable is 40% of that of the copper wire cable, and the construction and transportation costs are low. Aluminum is anti-oxidation and corrosion-resistant, so the aluminum wire is a must-have material for high-voltage, large-section, long-span overhead power transmission.

Is aluminum wire cable recyclable?

Common old aluminum wires and cables in life can be recycled. People mainly get aluminum in it, which requires the separation of aluminum and plastic wire sheath.

There are many ways to recycle aluminum wire. Such as the manual peeling method, burning method, freezing, and mechanical peeling method. But to recycle multi-strand wires or cables, all kinds of messy wires, car wires, home wires, network wires, electronic wires, and other raw materials, the mechanical crushing and grinding method of an aluminum wire recycling plant is required.

Video of copper aluminum wire recycling machine

Advantages of aluminum wire recycling machine

- Wide range of applications. Suitable for all kinds of wires and cables, automobile circuit lines, communication cables, network cables, square wires, and other waste wires with a diameter between 0.5-20mm. It can not only process thick square wire and cable wire but also process other materials like automobile wire, motorcycle wire, electric vehicle wire, network wire, communication wire, household appliance dismantling wire, electronic wire, and so on.

- Adoption of a three-in-one dust removal device. This dust removal device has three levels of dust removal: cyclone dust removal, bag dust removal, and air purifier dust removal, which effectively solves the problem of dust pollution.

- Environmentally friendly dry crushing method instead of washing. The raw materials such as waste cables and wires are crushed into a mixture of dry metals and plastics. The equipment will not produce water pollution.

- The copper and plastic are completely separated, and the separation rate can reach 97%-99.5%, which can achieve the purpose of comprehensive utilization and high economic benefits.

- Multi-machine combination structure and easy operation. One-time feeding, multi-machine completion, automatic conveying, sound insulation technology, a cooling system, etc. reflect high automation. Using the power distribution cabinet control, one person can complete the production operation, the operation is simple, and the maintenance is convenient.

- Integral combined structure and easy to install, debug, and transport. It can be used directly after the customer purchases it and turns on the power supply.

- Low noise and large output. The general capacity can reach 100-1000kg/h.

Process flow of aluminum cable recycling machine

Mechanical crushing method: This method adopts the method of crushing and sorting. The waste wires and cables are peeled by crushing, and then aluminum and plastic are separated by specific gravity separation, air separation, dust collection, and electrostatic separation. The method has a broad application scope, and at the same time, compared with mechanical peeling equipment, the output of the aluminum wire recycling machine is higher, and the manual work intensity is greatly reduced.

Process flow: The aluminum plastic separator machine uses a pulverizer to crush the material into a length of about 3cm, then undergoes secondary shearing pulverization, and then is sorted by high-precision airflow and vibrating screen to obtain plastic and aluminum, and the undivided plastic is then passed through sorting by electrostatic sorter to ensure the reuse rate of the metal.

Aluminum recycling machine structure and parameters

| Order | Product name | Picture | Specifications | Quantity |

| 1 | Crusher |  | Motor power: 30kw Blade material: H12 Screen Material: 314 / Carbon Steel | 1 |

| 2 | Air sorter |  | Dimensions: length 1500, width 700, height 2000mm Power: 6kw | 2 |

| 3 | Dust collector |  | Dimensions: length 1400, width 900, height 200mm Power: 5.5 kw Type: bag type dust collector | 1 |

| 4 | Electric control cabinet |  | Dimensions: length 600, width 400, height 1500mm | 1 |

| 5 | Vibrating screen |  | Dimensions: length 2200, width 700, height 1100mm Power: 0.75 kw | 2 |

| 6 | Crusher cutter |  | Size: length 325, width 80, thickness 20mm Material: H12 | 14 |

| 7 | Crusher screen |  | Size: 610mmx610mm Material: 314 | 1 |

Scrap aluminum recycling machine price

Aluminum wire recycling machine price is affected by many factors. Different materials cause different aluminum cable recycling machine prices. For a perfect and stable production line, it needs to consider the actual production situation, and increase certain auxiliary equipment, which will result in different prices. Customers should consider equipment materials, processing technology, the included accessories, services, etc.

An aluminum plastic separator machine normally contains the crusher, air separator, conveyor, and dust catcher, in addition to a magnetic separator, and vibrating screen. Besides, the customer may choose and buy some auxiliary equipment. Before purchasing an aluminum plastic separator machine, users need to understand their production capacity, and what kind of configuration in the process to reach the expected production effect.

How to increase the output of aluminum wire recycling machine?

In fact, the output of the aluminum plastic separator machine has a great relationship with the quality of the equipment, blades, and materials.

The important equipment to ensure the production volume and separation rate is the pulverizer and the booster electrostatic separation equipment in the copper rice machine production line. The two need to cooperate with each other to better improve the production efficiency of the copper aluminum wire recycling machine. If the production efficiency of the pulverizer is not high, it will directly lead to a decrease in the production efficiency of the scrap wire recycling machine. When working, it is necessary to ensure the uniformity of the feeding belt, not too fast or too slow.

When other conditions are equal, the automatic dry-type aluminum recycling machine will cut more thoroughly, with higher efficiency and longer service life, while the blades of poor quality will heat up and deform under high-intensity continuous work, thereby greatly reducing the working capacity of the automatic aluminum cable recycling machine. And in daily production, it is also necessary to understand the wear condition of the blades in the equipment, so as not to affect the production of the equipment.

If you have an interest in our aluminum wire recycling machine, please feel free to contact us for more machine details and quotations.