Air conditioner copper and aluminum separator is professional equipment for separating aluminum foil and copper pipe. This machine is suitable for separating copper and aluminum in waste air conditioner radiator and waste car radiator water tank. It has a high separation rate.

Structural composition of copper and aluminum separator

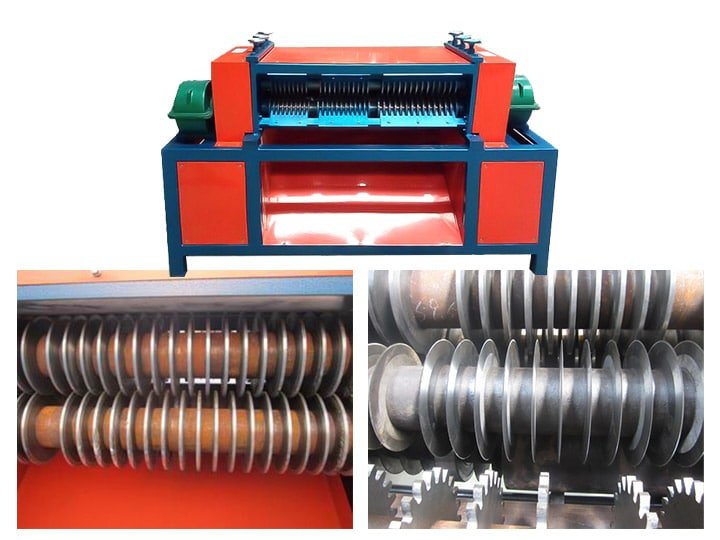

This machine is mainly composed of motor, speed reduction belt, pressure roller, cutter, machine body, and other parts.

Copper tube peeling machine

How does a copper-aluminum separator work?

After the material is manually fed into the machine, it is sent to the cutter section through the pressure roller. A high-speed rotating cutter cuts the aluminum foil and separates the copper tube. The working efficiency of this machine is very high, the separated aluminum is still block-shaped, and the copper pipe is not cut, which is very convenient for recycling and reuse.

Features of air conditioner copper and aluminum separator

1. The range of materials handled is very wide. One machine can handle single and double-layer radiators. Radiators with copper tube spacings of 19mm, 21mm, and 25mm can be separated using this machine.

2. There is almost no loss of material after separation. The copper tube is not deformed or damaged, and the aluminum foil is still an aluminum block, which does not generate dust to pollute the environment.

3. The operation of the machine is simple and convenient, saving human resources.

4. The machine is equipped with safety protection devices. The feeding inlet of the copper and aluminum separator is equipped with light eye control. If a person reaches the set position during work, the operation of the machine will stop.

AC Copper-aluminum seperator

copper-aluminum stripping machine

stock of this machine

Success case

Not long ago, a customer from India asked us more about copper and aluminum separators. After contacting our sales manager, he decided to buy three machines in our company

Technical Parameters

| Model | External dimension (mm) | Blade quantity (Pcs) | The diameter of the blade (mm) | Number of platens (per platen) | The diameter of the platen (mm) | Power (kW) | Weight (kg) |

| SY-850 | 1700*1000*1100 | 65 | 105+100 | 70 | 125 | 7 | 750 |

| SY-1200 | 2100*1150*1100 | 117 | 105+100 | 121 | 125 | 7 | 1250 |