The electrostatic separator is also called a high-voltage electrostatic separator. Through years of practice and theoretical analysis in our factory, it is continuously developed on the basis of international advanced technology. Today, this machine has achieved better sorting results. The impurity rate after sorting can be less than 3%, that is, the sorting effect can reach more than 98%, and it is a complete physical separation. After separation, the properties of various materials are not changed, and it does not affect recycling.

There are two main series of electrostatic separators

- Three roll type high-pressure separator.

- Double roll type high-pressure separator.

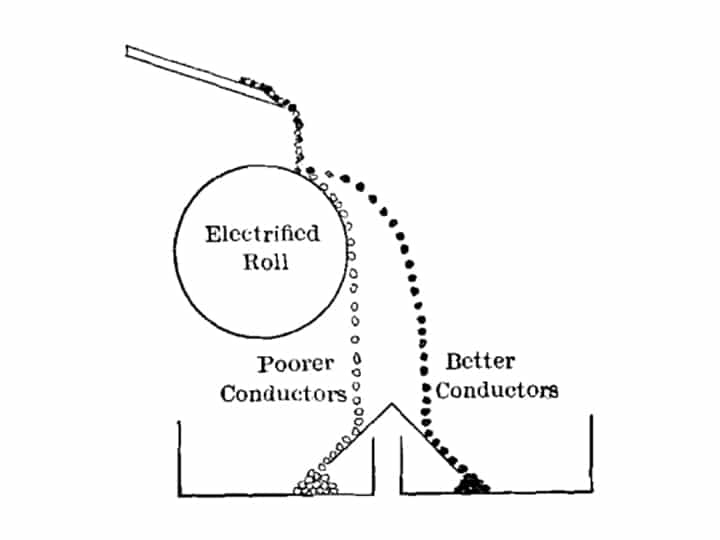

The electrostatic separator can separate more than 97% of the metals in the mixture, such as copper and aluminum, from plastic. The electrostatic separator solves the problem of separation yield and improves the yield. Different materials will have different separation effects. Before sorting, the conductivity of the materials should be tested to determine a better separation scheme.

Structural composition of electrostatic separation equipment

It consists of a feed inlet, negative pole, high voltage electric field, metal discharge opening, non-metallic material discharge opening, discharge brush, fuselage, overvoltage protection device, fuselage, and other components.

Features of electrostatic separator

1. It does not produce any pollution to the environment, does not use water, does not generate dust and other environmental pollution problems.

2. High separation efficiency, can separate metal and non-metal particles in a short time. The impurity ratio of the final product is less than 2%. For copper wires as thin as a hair, this machine can also be well separated.

3. Energy-saving and emission reduction. Compared with similar products in China, this machine can save 30% of energy consumption.

Scope of electrostatic separator

1. Separate metal from non-metal. At present, the more common applications on the market are aluminum-plastic separation, copper wire and plastic particle separation, circuit board powder and metal separation.

2. Plastics of different materials are separated.

3. Separation of metal ores.

4. Separation of tea leaves and tea stalks.

5. Isolation of flax seeds.

6. Separate metal ores from cinder.