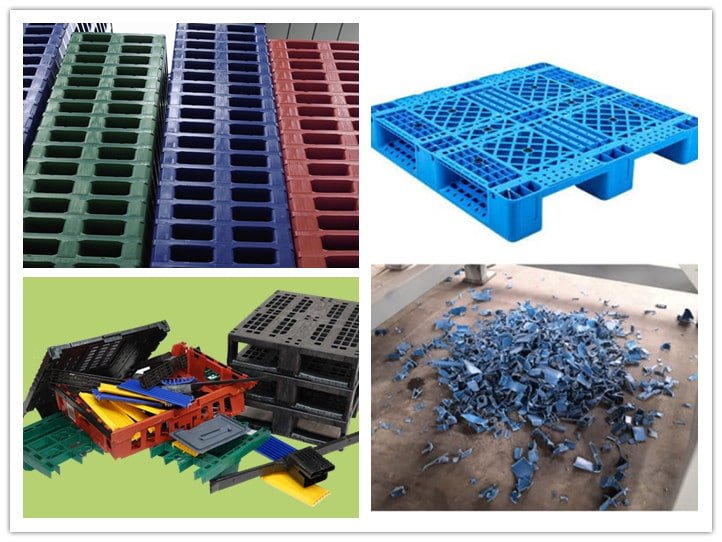

Тази машина за раздробяване на пластмасови палети може да разкъсва много видове суровини, включително кабели, гуми, коли, дърво, торби и други. Оборудването е подходящо за машината за професионална обработка на производствената линия за рециклиране на пластмаса. Обработените люспи от пластмасови отпадъци могат лесно да се опаковат, транспортират и рециклират.

Как работи машината за раздробяване на пластмасови палети в Япония?

Шредерът е двувалова трошачка с ниска скорост и висок въртящ момент. Всяка ос е оборудвана с въртящ се нож, който може надеждно да разкъса захранващия материал. Тази машина е подходяща за предварително раздробяване на тежки или обемисти материали (например битови отпадъци, промишлени отпадъци, търговски отпадъци, обемисти отпадъци и строителни отпадъци).

Характеристики на машина за раздробяване на пластмасови палети в Япония

- Целенасочен смачкващ ефект

Надеждно раздробяване и хомогенизираща обработка до необходимия размер на частиците.

Плавни стъпки на процеса надолу по веригата

- Ефективен ефект на двойно смачкване

Постига се мощен смачкващ ефект между въртящия се нож и шредерната маса или греда, фиксирана под вала

- Програма напред и назад

Мощно раздробяване на изключително грубия фураж

Предотвратете материалите да образуват мостове

- Икономични експлоатационни разходи

Въртящи се и неподвижни ножове за раздробяване натоварват равномерно по цялата дължина

Валът на ротора и масата за раздробяване могат да бъдат регенерирани многократно чрез заваряване с наслагване

- Високо използване

Дълъг живот на износващите се части

Бързо сменете вала на ротора чрез системата за бърза смяна

- Висока производителност

Задвижване с висок въртящ момент

Веднага може да се пусне на трисменен режим

- гъвкав

Декомпозирайте множество емисии

Благодарение на сравнително големия диаметър на вала, инструментът за раздробяване може безопасно да обработва дори големи или обемисти храни

- Интегрирана основна рамка на оборудването

Еднокомпонентната стоманена заварена конструкция е изключително здрава

Няма крехка болтова връзка

Дълъг живот на машината

Структура на машината за трошачка на пластмасови палети

- Бункер за фураж

Машината за раздробяване на пластмаса се подава през голям централен бункер за подаване. В допълнение към стандартните решения, бункерите могат да бъдат персонализирани и за клиенти.

- Корпус на машината

Корпусът на машината се състои от много здрава интегрирана стоманена заварена конструкция. Това също гарантира, че машината може лесно да издържи изключително високи натоварвания.

- Ножове за нарязване

Процесът на раздробяване се извършва между машинните валове, оборудвани с шредерни ножове и се осъществява от шредерната маса, греда и скрепер. Според ситуацията на захранване машината може да бъде оборудвана и със специален инструмент за раздробяване. Тези инструменти се различават по диаметър и форма. В тази връзка също е необходимо да се коригира структурата на шредера.

- Задвижващо устройство

Всеки колянов вал се задвижва независимо. Тази машина може да се задвижва от хидравличен или електрически двигател. И в двата случая се използва задвижващо устройство със стандартна индустриална трансмисия и устройство за регулиране на променлива скорост. Контролното устройство и задвижващото устройство могат да регулират последователността на превключване на посоката на въртене за натрошените материали.

- Хидравличен тласкач

Допълнителен хидравличен тласкач. Може да осигури непрекъснатост на храненето, когато обемът на хранене е голям, лек или партидно хранене.

- Шредери и греди

Долната част на двата роторни вала има шредер, греда и скрепер от една част с форма на кутия. Лесно се свалят и сменят при смяна на коляновия вал.

- Сменете вала

След разглобяване на захранващия бункер ще се разкрие роторният вал, проектиран с бърза връзка. Този бърз съединител се фиксира с болтове и може да замени коляновия вал, без да разглобявате предавателното устройство. Поради това валът на ротора може лесно да се отстрани.

Често задавани въпроси относно трошачката за пластмасови палети в Япония

Може ли машината за раздробяване на пластмасови палети да обработва отпадъци от гуми?

да

Може ли машината за трошане на пластмасови палети да бъде изпратена до Япония?

да

Какви са суровините за тази машина?

Машината за раздробяване на пластмасови палети може да раздробява дървени плоскости, отпадъчна кола, отпадъчни гуми, кабели и проводници, тъкани торби, отпадъчни пластмасови материали и други.

Как работи машината за раздробяване на пластмасови палети?

Той разкъсва суровини чрез пресоване на две ролки и ние предлагаме различни ролки според суровините.