Máy phân tách ACP là một thiết bị được sử dụng đặc biệt để tách các vật liệu composite nhôm-nhựa (như các tấm nhựa nhôm). Máy làm mềm chất kết dính của vật liệu nhựa nhôm bằng cách sưởi ấm, và nhôm và nhựa sẽ được tách ra một cách tự nhiên, nhận ra tái chế tài nguyên. Máy này có thể xử lý bất kỳ loại bảng nhựa nhôm nào có chiều rộng khoảng 600 mm đến 1000 mm, với công suất khoảng 4 tấn mỗi 8 giờ, có thể đáp ứng nhu cầu xử lý của hầu hết các nhà máy tái chế và các công ty tái chế.

Thiết bị phân tách tấm bằng nhôm là thiết bị tiên tiến, tách các tấm ACP thành nhôm và nhựa. Máy tước ACP phế liệu áp dụng sự phân tách vật lý khô, không gây ô nhiễm môi trường, có lợi ích kinh tế và xã hội tốt, và có triển vọng thị trường rộng lớn.

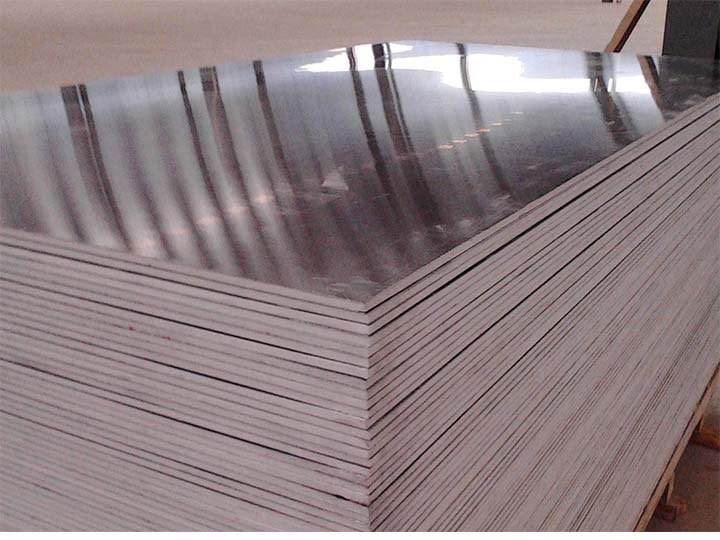

Bảng ACP là gì?

Một bảng tổng hợp nhôm (ACP) là một loại vật liệu trang trí xây dựng mới, thường thấy trong cuộc sống hàng ngày của chúng ta. Bảng tổng hợp ba lớp có nhựa làm lớp lõi và nhôm ở cả hai bên. Do sản lượng cao và sử dụng rộng các tấm ACP, một lượng lớn chất thải được tạo ra, trong khi giá trị tái chế của nhôm trên bề mặt của các tấm nhựa nhôm cao.

Phương pháp tái chế nhôm phổ biến là mở phần cuối của bảng điều khiển ACP và sau đó bóc lớp nhôm. Tách lớp nhôm và lớp nhựa của bảng composite nhôm không dễ như nhiều người nghĩ. Nó đòi hỏi công nghệ tách chuyên nghiệp của thiết bị.

Triển vọng thị trường của việc tái chế tấm nhôm tổng hợp (ACP)

Là một loại vật liệu trang trí tòa nhà mới, bảng điều khiển ACP có nhiều cách sử dụng vì hiệu suất xử lý tuyệt vời của nó. Nó có thể được sử dụng để xây dựng các bức tường bên ngoài, tấm tường rèm, cải tạo và cải tạo các tòa nhà cũ, tường nội thất và trang trí trần, biển báo quảng cáo, khán đài hiển thị và các dự án khác. Với sự gia tăng dần dần của các bảng ACP trên thị trường, việc xử lý ACP phế liệu cũng đã dần dần phát triển. Để có hiệu quả tái chế cao, cần phải áp dụng máy tái chế ACP đáng tin cậy với công nghệ tách biệt trưởng thành.

Tại sao chúng ta cần một máy phân tách ACP?

1. Hiệu suất cao, vận hành đơn giản, tiết kiệm thời gian và nhân lực.

Phương pháp rang lửa truyền thống đòi hỏi người thợ phải bóc vỏ bằng sức lực, thời gian làm việc kéo dài. Cần 2 công nhân nam, kéo 2 bên, đòi hỏi nhiều kỹ năng và sức lực.

Máy tách ACP được kéo bằng lực cơ học và vận hành dễ dàng, dễ dàng. Nó chỉ cần đẩy vật liệu vào cổng theo cách thủ công và sau khi vật liệu chảy ra, lớp lá nhôm và lớp nhựa có thể dễ dàng tách ra bằng tay. Sản lượng có thể đạt 400-1000kg/h.

2. Vận hành an toàn và đáng tin cậy, không lãng phí nguyên liệu.

Đầu vào nguồn cấp dữ liệu và hệ thống sưởi ấm được thiết kế hợp lý để đảm bảo vận hành an toàn. Phương pháp rang lửa truyền thống đòi hỏi trình độ tay nghề cao của người thợ. Vì bảng ACP được đặt trên lửa nên ngọn lửa sẽ thoát ra dọc theo gờ khi bong ra và rất dễ làm cháy vật liệu.

3. Tiết kiệm năng lượng và tiết kiệm chi phí.

Động cơ chính của máy tước tấm ACP chỉ có công suất 2,2kw và mức tiêu thụ điện năng thấp. Máy tước tấm ACP có thể tiết kiệm đáng kể chi phí nhân công.

4. Máy tái chế bảng ACP không gây ô nhiễm và có tiếng ồn thấp.

5. Cấu trúc đơn giản, hiệu suất ổn định và đáng tin cậy, và tuổi thọ dài.

Video máy tách phế liệu ACP

Cấu trúc chính của máy tái chế bảng ACP

Máy tách ACP phế liệu bao gồm cơ cấu bóc, cơ cấu xả, con lăn, bánh xích, cơ cấu trợ lực, v.v. Cơ cấu trợ lực bao gồm một động cơ và hộp số. Đầu ra của động cơ được nối với đầu vào của hộp số thông qua dây đai. Cấu trúc máy hợp lý và công việc ổn định.

Làm thế nào để tách nhôm khỏi tấm nhôm composite?

Do quy trình tổng hợp của tấm ACP được tạo thành từ hỗn hợp nhiệt ở nhiệt độ cao nên máy tách ACP có thể tách nhôm và nhựa sau khi nung đến nhiệt độ đặt trước rồi nung. Nói một cách đơn giản, công nghệ bóc tách của tấm ACP là tách một lớp lá nhôm và nhựa của tấm nhôm composite.

Máy tước tấm ACP do Shuliy Machinery sản xuất áp dụng phương pháp tách bằng cách đẩy khí đốt hóa lỏng đốt nóng hoặc đốt nóng bằng điện để tách lớp nhôm và lớp nhựa. Nói một cách đơn giản, máy sẽ nung bề mặt của các tấm nhôm composite bằng lửa trần, làm mềm nó rồi xé nó ra bằng tay.

Thông số kỹ thuật của máy phân tách trang ACP

Máy phân tách ACP của chúng tôi có các loại và mô hình khác nhau. Sau đây là mô hình chung. Điện áp tiêu chuẩn của máy là 380V/50Hz. Chúng tôi có thể tùy chỉnh nó để đáp ứng các nhu cầu đặc biệt, bao gồm điện áp, kích thước, công suất, v.v ... Tốc độ tách nhôm cao tới 99%, có thể làm tăng đáng kể giá trị kinh tế.

| Người mẫu | SL-600 | SL-800 | SL-1000 |

| Chiều rộng làm việc | 400mm | 600mm | 800mm |

| Áp dụng | Tất cả các loại vật liệu ACP | Tất cả các loại vật liệu ACP | Tất cả các loại vật liệu ACP |

| Kích thước (L*W*H) | 1400*1500*1100mm | 3900*2300*1100mm | 3900*2500*1100mm |

| Cân nặng | 800kg | 1200kg | 1300kg |

| Điện áp (có thể tùy chỉnh) | 380V/2,2kW, 50Hz, 3 pha | 380V/4kW, 50Hz, 3 pha | 380V/4kW, 50Hz, 3 pha |

| Dung tích | 4T/8 giờ | 4T/8 giờ | 4T/8 giờ |

| Tiêu thụ khí | 2,5kg/h | 3,75kg/h | 4kg/h |

Máy liên quan: Máy đóng vỉ nhôm nhựa

Trong việc tái chế các gói nhựa nhôm blister, nhôm và nhựa cũng cần được tách ra. Thiết bị thường được sử dụng là một nhà máy tái chế phế liệu gói blister. Quy trình sản xuất cần trải qua công nghệ nghiền, xay và phân loại, và các sản phẩm cuối cùng là bột nhôm và bột nhựa.