The electrostatic separator (aluminum-plastic separator) uses the principle of different conductivity of objects to separate conductive and non-conducting substances in a high-voltage electric field. In terms of cable recycling, this machine mainly separates plastic and copper particles to achieve the purpose of complete separation.

Application range of electrostatic separator

- Extract metal materials from plastic. For example, the separation of aluminum and plastic in aluminum-plastic medicine board, the separation of copper in circuit boards, and the separation of copper in cables and wires

- Separate metal powder from carbon. Such as the separation of carbon-containing mixtures of aluminum foil.

- Separate different types of plastic materials. The electrostatic separator can sort PE, PET, ABS, HDPE and other materials.

- Sorting of different metal ores. Can be applied to the sorting of magnetite, hematite, and Luo iron ore;

- Separation of non-metallic ore. Such as the separation of quartz and feldspar; the separation of graphite, diamond, apatite.

- Separation of other materials: decarbonization of coal ash, separation of slag ash and metal, separation of plastic and sand, separation of tea and tea rods, separation of flax seed kernels and shells, separation of hair and other materials.

What is the working principle of electrostatic separator?

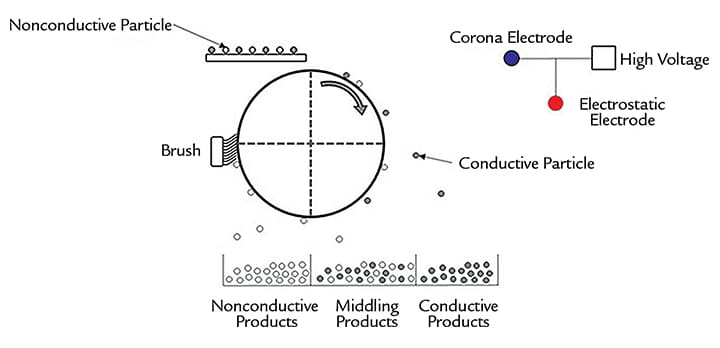

The inside of the electrostatic separator is a high-voltage electric field. After the material enters the machine, it will be bound with positive or negative charges according to different electrical conductivity. Unlike the electric charge in the wire, this charge cannot be moved. Therefore, this charge is called electrostatic charge.

The specific process is as follows

- The electrostatic separator uses materials with different conductivity to separate materials.

- There is a high-voltage electric field inside the machine.

- After the material enters the machine, the material is evenly distributed on the negative electrode roller by the vibration motor.

- The negative electrode roller continuously rotates, bringing the material into the positive electrode field.

- Metal particles with good electrical conductivity are not affected and fall from the outlet of the metal material.

- The plastic particles carry the negative charge and are adsorbed on the negative electric roller. It is then swept by a brush and falls from a non-metallic outlet.

What are the common separation methods?

Common methods for separating plastics and copper are water separation and electrostatic separation.

The water separation method mainly uses different densities of materials for sorting. Copper has a higher density and will sink to the bottom of the water; low-density plastic will float on the water. The water separation method is the most primitive separation method. Although the equipment is cheap, it is gradually eliminated by society due to poor separation effect and sewage discharge.

Features of electrostatic separator

1. Protect the environment. In the sorting process, no water is used, no dust is generated, and there is no secondary pollution to the environment.

2. Good separation effect. In the secondary separation process, the separation efficiency of copper and plastic can reach more than 99%.

3. Simple operation, only one person can complete the work.

4. Energy-saving and low noise.

Technical Parameters of the Aluminum-plastic separator:

| Model | External dimension(mm) | Rotary drum dia. (mm) | Speed(r/min) | Power(kW) | Sorting voltage(v) | Particle requirements(mm) | Weight(kg) |

| SY-1000 | 1800*1350*3500 | 320 | 30-900 | 3.6 | 20-60000 | 0.01-4 | 1250 |

| SY-1500 | 2300*1350*3500 | 320 | 30-900 | 5.5 | 20-70000 | 0.01-4 | 1500 |

| SY-1800 | 2650*1350*3600 | 320 | 30-900 | 7.5 | 20-80000 | 0.01-4 | 1850 |