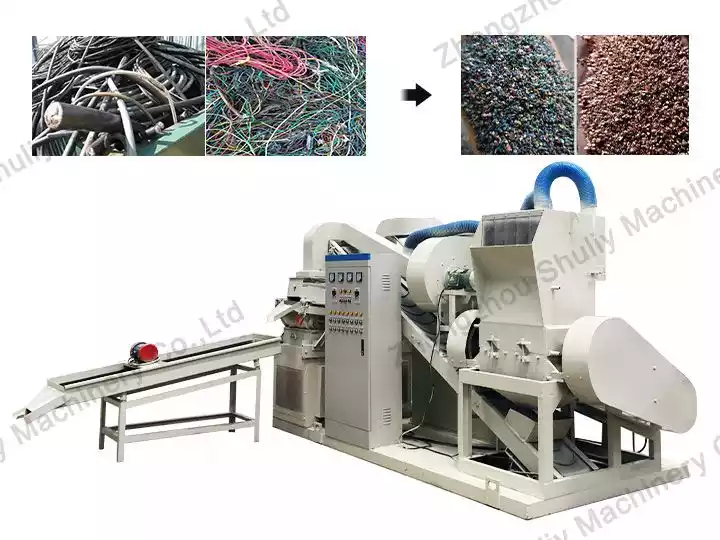

Eine Aluminiumdraht-Recyclingmaschine (auch bekannt als Kupferdraht-Granulator) wird verwendet, um nach dem Zerkleinern Kupfer oder Aluminium von Kunststoff zu trennen. Eine Aluminiumkabel-Recyclingmaschine ist eine Art Umweltschutzmaschine mit einfacher Struktur und ausgereifter Technologie.

Das Produktionsprinzip der Trocken-Aluminium-Kunststoff-Trennmaschine besteht hauptsächlich darin, die Trockentechnologie zum Pulverisieren zu verwenden und spezifische Schwerkraft-, magnetische oder elektrostatische Trennmethoden zu verwenden, um Nichtmetalle und Metalle zu trennen.

Als Hersteller von Altdraht-Recyclingmaschinen können wir Geräte mit unterschiedlichen Sortiereffekten und angemessenen Leistungen entsprechend den Anforderungen der Benutzer entwerfen und produzieren. Aluminiumdraht-Recyclinganlagen können den Kunden erhebliche Vorteile bei der Ressourcenrückgewinnung bringen.

Einführung in Aluminiumdraht

Unter Aluminiumdraht versteht man ein drahtförmiges Metallmaterial aus reinem Aluminium oder einer Aluminiumlegierung. Die Querschnittsformen sind Kreis, Ellipse, Quadrat, Rechteck, gleichseitiges Dreieck und regelmäßiges Vieleck usw. Je nach Verwendungszweck wird in Industriealuminiumdraht und Prozessaluminiumdraht unterteilt. Das Aluminiumkabel und der Aluminiumdraht sind sehr leicht, das Gewicht des Aluminiumdrahts und des Aluminiumkabels beträgt 40% des Kupferdrahtkabels und die Bau- und Transportkosten sind niedrig. Aluminium ist antioxidativ und korrosionsbeständig, daher ist der Aluminiumdraht ein unverzichtbares Material für die Hochspannungs-Freileitungsübertragung mit großem Querschnitt und großer Spannweite.

Ist Aluminiumdrahtkabel recycelbar?

Im Leben übliche alte Aluminiumdrähte und -kabel können recycelt werden. Es enthält hauptsächlich Aluminium, was die Trennung von Aluminium und Kunststoffdrahtmantel erfordert.

Es gibt viele Möglichkeiten, Aluminiumdraht zu recyceln. Wie die manuelle Schälmethode, die Brennmethode, das Einfrieren und die mechanische Schälmethode. Aber um mehradrige Drähte oder Kabel, alle Arten von unordentlichen Drähten, Autokabeln, Heimkabeln, Netzwerkkabeln, elektronischen Kabeln und anderen Rohstoffen zu recyceln, ist die mechanische Zerkleinerungs- und Mahlmethode einer Aluminiumdraht-Recyclinganlage erforderlich.

Video einer Kupfer-Aluminium-Draht-Recyclingmaschine

Vorteile der Aluminiumdraht-Recyclingmaschine

- Breites Anwendungsspektrum. Geeignet für alle Arten von Drähten und Kabeln, Kfz-Stromkreisleitungen, Kommunikationskabel, Netzwerkkabel, Vierkantdrähte und andere Abfalldrähte mit einem Durchmesser zwischen 0,5 und 20 mm. Es kann nicht nur dicke Vierkantdrähte und Kabeldrähte verarbeiten, sondern auch andere Materialien wie Automobildraht, Motorraddraht, Elektrofahrzeugdraht, Netzwerkdraht, Kommunikationsdraht, Demontagedraht für Haushaltsgeräte, Elektronikdraht usw. verarbeiten.

- Einführung eines Drei-in-Eins-Staubentfernungsgeräts. Dieses Staubentfernungsgerät verfügt über drei Staubentfernungsstufen: Zyklon-Staubentfernung, Beutelstaubentfernung und Luftreiniger-Staubentfernung, wodurch das Problem der Staubverschmutzung effektiv gelöst wird.

- Umweltfreundliche Trockenzerkleinerungsmethode statt zu waschen. Die Rohstoffe wie Kabel- und Leitungsabfälle werden zu einer Mischung aus trockenen Metallen und Kunststoffen zerkleinert. Das Gerät verursacht keine Wasserverschmutzung.

- Kupfer und Kunststoff sind vollständig getrenntund die Trennrate kann 97%-99,5% erreichen, wodurch der Zweck einer umfassenden Nutzung und hoher wirtschaftlicher Vorteile erreicht werden kann.

- Mehrmaschinen-Kombinationsstruktur und einfache Bedienung. Einmalige Beschickung, Mehrmaschinenkomplettierung, automatische Förderung, Schallschutztechnik, Kühlsystem usw. spiegeln eine hohe Automatisierung wider. Mit der Steuerung des Stromverteilerschranks kann eine Person den Produktionsvorgang abschließen, die Bedienung ist einfach und die Wartung ist bequem.

- Integrierte, kombinierte Struktur und einfach zu installieren, zu debuggen und zu transportieren. Es kann direkt nach dem Kauf durch den Kunden und dem Einschalten der Stromversorgung verwendet werden.

- Geringes Rauschen und große Leistung. Die allgemeine Kapazität kann 100–1000 kg/h erreichen.

Prozessablauf einer Aluminiumkabel-Recyclingmaschine

Mechanische Zerkleinerungsmethode: Diese Methode übernimmt die Methode des Zerkleinerns und Sortierens. Die Abfalldrähte und -kabel werden durch Zerkleinern geschält, und anschließend werden Aluminium und Kunststoff durch spezifische Schwerkrafttrennung, Lufttrennung, Staubsammlung und elektrostatische Trennung getrennt. Das Verfahren hat ein breites Anwendungsspektrum und gleichzeitig ist die Leistung der Aluminiumdraht-Recyclingmaschine im Vergleich zu mechanischen Schälgeräten höher und die manuelle Arbeitsintensität wird erheblich reduziert.

Prozessablauf: Die Aluminium-Kunststoff-Trennmaschine verwendet einen Pulverisierer, um das Material auf eine Länge von etwa 3 cm zu zerkleinern, durchläuft dann eine sekundäre Scherpulverisierung und wird dann durch einen hochpräzisen Luftstrom und ein Vibrationssieb sortiert, um Kunststoff und Aluminium sowie den ungeteilten Kunststoff zu erhalten Anschließend wird es durch einen elektrostatischen Sortierer sortiert, um die Wiederverwendungsrate des Metalls sicherzustellen.

Struktur und Parameter der Aluminiumrecyclingmaschine

| Befehl | Produktname | Bild | Spezifikationen | Menge |

| 1 | Brecher |  | Motorleistung: 30 kW Klingenmaterial: H12 Bildschirmmaterial: 314 / Kohlenstoffstahl | 1 |

| 2 | Luftsortierer |  | Abmessungen: Länge 1500, Breite 700, Höhe 2000 mm Leistung: 6 kW | 2 |

| 3 | Staubsammler |  | Abmessungen: Länge 1400, Breite 900, Höhe 200 mm Leistung: 5,5 kW Typ: Beutel-Staubsammler | 1 |

| 4 | Elektrischer Schaltschrank |  | Abmessungen: Länge 600, Breite 400, Höhe 1500 mm | 1 |

| 5 | Vibrationssieb |  | Abmessungen: Länge 2200, Breite 700, Höhe 1100 mm Leistung: 0,75 kW | 2 |

| 6 | Brecherschneider |  | Größe: Länge 325, Breite 80, Dicke 20 mm Material: H12 | 14 |

| 7 | Brechersieb |  | Größe: 610 mm x 610 mm Material: 314 | 1 |

Preis für Aluminiumschrott-Recyclingmaschine

Der Preis einer Aluminiumdraht-Recyclingmaschine wird von vielen Faktoren beeinflusst. Unterschiedliche Materialien führen zu unterschiedlichen Preisen für Aluminiumkabel-Recyclingmaschinen. Für eine perfekte und stabile Produktionslinie muss die tatsächliche Produktionssituation berücksichtigt und bestimmte Zusatzgeräte erhöht werden, was zu unterschiedlichen Preisen führt. Kunden sollten Ausrüstungsmaterialien, Verarbeitungstechnologie, enthaltenes Zubehör, Dienstleistungen usw. berücksichtigen.

Eine Aluminium-Kunststoff-Trennmaschine enthält normalerweise einen Brecher, einen Luftabscheider, ein Förderband und einen Staubfänger sowie einen Magnetabscheider und ein Vibrationssieb. Außerdem kann der Kunde einige Zusatzgeräte auswählen und kaufen. Vor dem Kauf einer Aluminium-Kunststoff-Trennmaschine müssen Benutzer ihre Produktionskapazität und die Art der Konfiguration im Prozess kennen, um den erwarteten Produktionseffekt zu erzielen.

Wie kann die Leistung einer Aluminiumdraht-Recyclingmaschine gesteigert werden?

Tatsächlich steht die Leistung der Aluminium-Kunststoff-Trennmaschine in engem Zusammenhang mit der Qualität der Ausrüstung, Klingen und Materialien.

Die wichtige Ausrüstung zur Sicherstellung des Produktionsvolumens und der Trennrate ist der Pulverisierer und die Ausrüstung zur elektrostatischen Booster-Trennung in der Produktionslinie für Kupferreismaschinen. Die beiden müssen zusammenarbeiten, um die Produktionseffizienz der Kupfer-Aluminium-Draht-Recyclingmaschine besser zu verbessern. Wenn die Produktionseffizienz des Pulverisierers nicht hoch ist, führt dies direkt zu einer Verringerung der Produktionseffizienz der Altdraht-Recyclingmaschine. Beim Arbeiten ist darauf zu achten, dass das Zuführband gleichmäßig ist, weder zu schnell noch zu langsam.

Wenn andere Bedingungen gleich sind, schneidet die automatische Trocken-Aluminium-Recyclingmaschine gründlicher, mit höherer Effizienz und längerer Lebensdauer, während sich die Klingen von schlechter Qualität bei hochintensivem Dauerbetrieb erwärmen und verformen, wodurch der Arbeitsaufwand erheblich reduziert wird Kapazität der automatischen Aluminiumkabel-Recyclingmaschine. Und in der täglichen Produktion ist es auch notwendig, den Verschleißzustand der Messer in der Anlage zu verstehen, um die Produktion der Anlage nicht zu beeinträchtigen.

Wenn Sie Interesse an unserer Aluminiumdraht-Recyclingmaschine haben, kontaktieren Sie uns bitte für weitere Maschinendetails und Angebote.