A double shaft plastic shredder machine could process electric wire, cable, plastic products, pallets, waste tyres, cars, and other materials. We provide different rollers for customer choice according to their raw materials. And this wire and cable shredder have a large capacity and great crushing effect. It can also be equipped with other machines to form a waste electric wire recycling production line.

Industrial double shaft plastic shredder machine Introduction

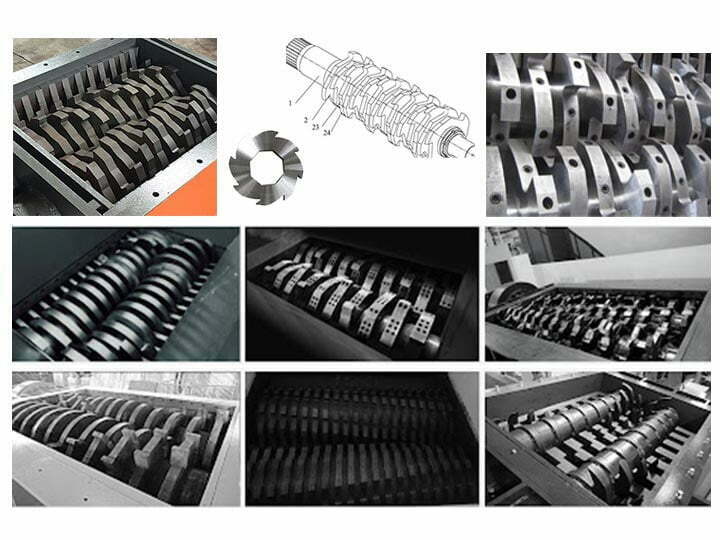

Wire and cable shredder equipment mainly process copper wires, aluminum wires, data wires, lighting wires, power wires, communication cables, etc. Put the messy wires into the shredder hopper. The wire is squeezed and shredded into small pieces by a high-speed toothed roller, and then discharged from the discharge port. It can also be used with a conveyor belt to transport the shredded wires to the next machine for further processing. There are multiple types of rollers according to different raw materials so the double shaft plastic shredder machine could achieve the best working effect.

Application of wire and cable shredder equipment

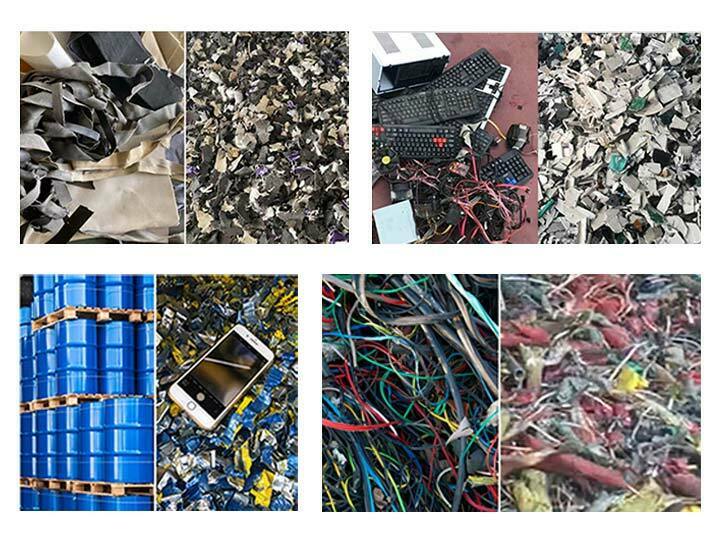

Plastic products: plastic bottle, PP container, PE container, PVC/PET waste.

The agricultural film, plastic film.

PET sheet, pallet.

Pipe, waste tyres, rubber tyres.

Woven bag, dead animal(the shredded meat can be made into fodder, provender, forage, mash to feed poultry).

Electronic scrap, wire and cable, copper wire, aluminum wire, data line, lighting line, power line, communication cable.

Technical parameter of Industrial double shaft plastic shredder equipment

| Model | PC260 | PC300 | PC400 | PC500 | PC600 | PC800 | PC1000 |

| Power | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 37-45 |

| Scrap room | ф200*230 | ф220*300 | ф245*400 | ф280*500 | ф410*600 | ф410*800 | ф410*1000 |

| Moving knife | 6 | 9 | 12 | 15 | 18 | 24 | 30 |

| Fixed knife | 2 | 2 | 2 | 2 | 4 | 4 | 4 |

| Amount of scrap | 100-150 | 150-250 | 250-350 | 350-450 | 500-600 | 600-800 | 800-1000 |

| Screen aperture | ф8 | ф10 | ф10 | ф10 | ф10 | ф10-ф16 | ф10-ф25 |

| Mechanical Dimensions | 100*70*105 | 110*80*120 | 130*90*135 | 140*100*145 | 145*125*175 | 150*140*180 | 180*170*190 |

| Weight | 340 | 480 | 660 | 870 | 1010 | 1250 | 2200 |

Electric wire crusher Spotlights

- The design of this machine is reasonable, and the body is welded with high-quality steel.

- Fastened with high-strength screws, solid structure and durable.

- The design of the main machine is exquisite, and the shredded material adopts a separate design to make the output higher.

- The processed and broken pieces are uniform and the loss is small. Multiple screens can be replaced at the same time to meet different needs.

- At the same time, it is equipped with tools of different materials in order to target different materials. The tool can be adjusted telescopically, and can be ground after being blunt. It can be used many times and has a long service life.

- This machine has advanced structure, beautiful appearance, easy operation and stable operation. The advantages of low investment and high efficiency.

- Equipped with an enlarged pulley to increase the inertia of the crusher, which can save energy and powerfully crush.

What are the factors affecting the production status of double shaft plastic shredder?

- Hardness of raw material

Under normal circumstances, the greater the hardness, the more difficult the production and processing of the shredder, and the greater the resistance it receives, and the greater the hardness, the wear on the shredder will be greater than that of the general hardness. Therefore, the shredder has a slow speed but high power, which is specially used to shred materials with higher hardness.

- Moisture and humidity

If the material of the shredder has high humidity, it may cause the material to stick to the shredder or its cutter during the production process, and it is also not conducive to the screening work.

- Material composition

- Material viscosity

This is the same as the second effect of the shredder, which easily causes materials to stick to the machine.